In the case of test and measurement, cable and connector installations, and coaxial assemblies, there is substantial design effort and thought dedicated to selecting the optimal coaxial cables and connectors for the project. These factors include electrical properties, mechanical properties, infrastructure logistics, pricing, environmental ratings, and standards and qualifications.

In the case of test and measurement, cable and connector installations, and coaxial assemblies, there is substantial design effort and thought dedicated to selecting the optimal coaxial cables and connectors for the project. These factors include electrical properties, mechanical properties, infrastructure logistics, pricing, environmental ratings, and standards and qualifications.

However, there is more to a coaxial assembly and installation than just the cables and connectors. These handy RF tools must be installed with hardware and components that ensure good RF operation and electrical isolation. Additionally, maintenance is also a common occurrence, and there are tools that are necessary to perform field and factory repairs to these system. This post will briefly walk through several coaxial cable and connector accessories and assembly/repair tools that are frequently used to ensure proper device and system operation over the lifetime of the project.

EMI/RFI Gaskets

Though the shielding of a coaxial cable assembly provides a high isolation against invasive signals from the surrounding environment, the connections between the bulkhead connector and housing aren’t always as well shielded. Hence, EMI/RFI gaskets can be used to ensure a complete seal of the bulkhead connector and the metallic housing of a coaxial assembly, which can provide a higher level of isolation of the overall assembly.

Depending on the type of connector format, both ring and flat gaskets are available. For example, with SMA gaskets, flat 4 hole flange connector gaskets are common, as well as ring gaskets.

Nuts & Bolts

Many bulkhead, or flange, coaxial connectors require nuts and bolts to connect to an assembly. Often, knowing the exact type, size, and threading of the screw is necessary to properly connect the flange to a housing. Material composition for these screws is sometimes very important, as certain environmental factors can cause galvanic corrosion, or other deterioration effects, which may eventually reduce device/system performance or cause failures. Fasteners are a common failure mode for complex assemblies and systems.

Brackets and Other Hardware

The mechanical stresses that inline coaxial components undergo can be significant. Typical coaxial cables and connectors are design for a certain level of acceptable stress, but any break in the line for an inline component can concentrate those stresses in that point of non-continuity. Hence, brackets, ties, and other supporting structures are often valuable to ensure consistent placement and reduces stresses at those critical junctions.

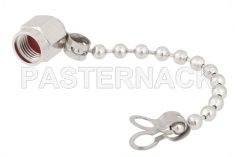

Dust Caps With/Without Chains

Dust Caps With/Without Chains

Be it indoors or outdoors, dust and particulate debris can be an issue with any coaxial system. Any particles inside a coaxial connector or line can reduce the RF performance and even lead to sparking and failure at high power levels. With the nature of RF energy, even coaxial ports of an assembly that go unused need to be properly terminated to avoid interaction with the outside environment and environmental or interference ingress.

Coaxial connector dust caps were specifically designed to provide an additional level of environmental protection compared to standard terminations. Also, many of these dust caps can provide shorting or non-shorting terminations, depending on the electrical requirements of a specific port. Moreover, some dust caps are available with security chains to prevent loss and damage of the cap if a port requires frequent access.

Pasternack Blog

Pasternack Blog